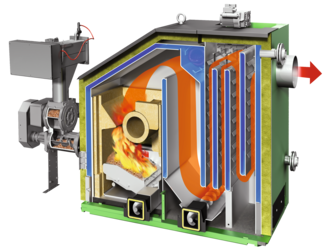

The blue sections in this diagram are the water channels, you can see how narrow they are.

In this article we aim to explain why power flushing the water heating side of your boiler can help reduce system faults and greatly increase the efficiency of the boiler which in turn saves you fuel and down time.

Many biomass boilers have now been in service for many years, and over that period the water in the system can have been lost through minor leaks and maintenance procedures. The system is then often topped up with plain tap water, thus diluting the inhibitor that was added when the system was new to stop the water calcifying in the boiler jacket and other important areas of the pipework, like the sensors that monitor the system and regulate it’s control.

Along with the faults that a clogged system generates, it has a massive effect on the efficiency of the boiler with the heat from the fire box been unable to easily transfer to the water in the system as the calcium acts as a layer of insulation stopping the heat from been transferred.

Lack of inhibitor causes these faults:

- Burn out of the stepped grate in the firebox as the water on the other side is not drawing the heat away sufficiently.

- The control systems of the boiler failing to operate in a consistent manner due to encrusted sensors.

- Limescale and calcium deposits drags the efficiency of the boiler down to unacceptable levels.

On a recent servicing call we flushed 50 kg of calcium out of the water system of the boiler alone, this was having a dramatic effect on the heat output performance.

Equipment that can benefit from power flushing:

- The Boiler

- Heat exchangers

- Large radiators

Once we have power flushed the system clean, we have the necessary equipment to refill the system with the correct amount of inhibitor and to the correct pressure, ensuring there are no air locks and leaving your boiler in the best shape it can be and fit for another decade of service. This can all be done as part of our scheduled maintenance of your boiler, see our Servicing Options for more details.